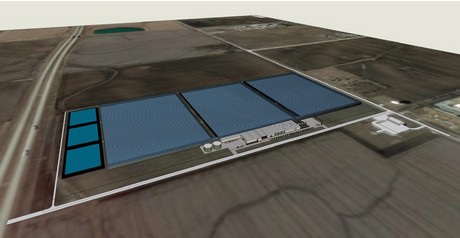

Photo courtesy of Bushel Boy Farms

Minnesota-based Bushel Boy Farms is expanding with a new 50-acre facility in Mason City, Iowa. The $35 million investment in the new facility will increase current production by 50% and is expected to bring approximately 50 full-time jobs to the city. Tomatoes will be the initial crop.

VB Greenhouse Projects from the Netherlands has been recently awarded the contract for this modern greenhouse complex to be built in Northern Iowa. The groundbreaking, which took place on Sept. 11, commences phase one of a three-phase project and entails development of a 16.5-acre high-tech greenhouse with a modern packhouse and technical installations building. The foundation works are to commence immediately. The project is scheduled for completion in October 2020, with the first harvest expected in December of that year.

Bushel Boy is also building in its base of Owatonna, Minnesota, as construction is currently underway on a 4.5-acre research and development greenhouse also built by VB Greenhouse Projects. This state-of-the-art expansion will both increase production at its flagship facility and increase the variety of tomato offered. The construction phase of this R&D project is already set for completion in December 2019 with production starting in early 2020.

Bushel Boy - Mason City 1

Bushel Boy - Mason City 2

Bushel Boy - Mason City 3

Once both projects are complete, Bushel Boy will have 48 acres of greenhouse space, with infrastructure in place for 33 more acres. These projects will provide the company an enhanced ability to offer a wide variety of locally grown, premium fresh produce to the upper Midwest.

Latest from Produce Grower

- Chilli thrips (Scirtothrips dorsalis)

- GS1 US Celebrates 50-Year Barcode 'Scanniversary' and Heralds Next-Generation Barcode to Support Modern Commerce

- University of Florida offers Greenhouse Training Online program on irrigation water

- Flower trends in full bloom

- Nominate an outstanding leader

- New Florida Extension Agent Will Teach Stakeholders About Food Safety

- Paint it black

- Regular checkups