Editor's Note: This article originally appeared in the May/June 2025 print edition of Produce Grower under the headline “Striving for efficiency.”

Labor is usually the greatest expense item in the production of greenhouse vegetable crops. During the past few years, considerable equipment has been developed that can aid in making normal hand tasks less labor intensive. Examples include motorized lifts, stringing and hook winding machines, vertical sprayers, deleafers, harvesting trolleys, tomato sorting machines and robot harvesters.

The following is a short review of some of these machines, most of which have been developed in Europe and China.

Scissor lifts

High-wire production has become the standard in tomato, cucumber and pepper production. Maintenance, such as suckering, clipping, wrapping, leaf removal, pinching and harvesting, of these crops is best done from a motorized scissor lift. Lifts can either be rubber-tired for use on a walkway or mounted on pipe rails at the base of the plants. Most are powered by 24-volt electric motors with controls at operator level. The lifts are designed to fit narrow row spacing and are available with work heights to about 20 feet.

Transport trolleys

Designed for moving harvested fruit from the growing to the packing area, these can be manufactured to fit different rail spacing and carton size. This machine has push handles, brakes and rubber swivel center wheels to move on concrete walkways.

Stringing and hook winding machines

Crops such as tomatoes are usually supported by string attached from an overhead support wire to the base of the plant. An automatic stringing machine can cut the string to a predetermined length at a rate of up to 1,500 strings per hour. Mounted on the scissor lift, the grower can attach the string to the support wire as the trolley travels along the growing bed Formed wire hooks are used to allow adjustment of the plant support twine. They usually hold 30 to 50 feet of twine and are reusable by adding new twine; they can wrap up to six hooks at one time at a rate of about 250 per hour.

Tomato plant deleafing robots

Removing the lower leaves of tomato plants reduces the incidence of disease and allows more light to reach the fruit. A recently developed robot from French engineers at Aisprid detects the leaf to be removed and cuts it off with precision. The leaf is dropped in the aisle to be collected later (this can be done with a leaf vacuum), and the knife is sterilized. The machine is self-contained and operates on pipe rails.

Vertical boom chemical sprayers

These machines are available as either pipe rail-mounted with separate transport wheels or rubber tire-mounted for flat aisle surfaces. Options include a hose reel model with material supplied from a central tank or a trolley model with a chemical tank and high-pressure pump. Some units can apply several spray materials in one pass.

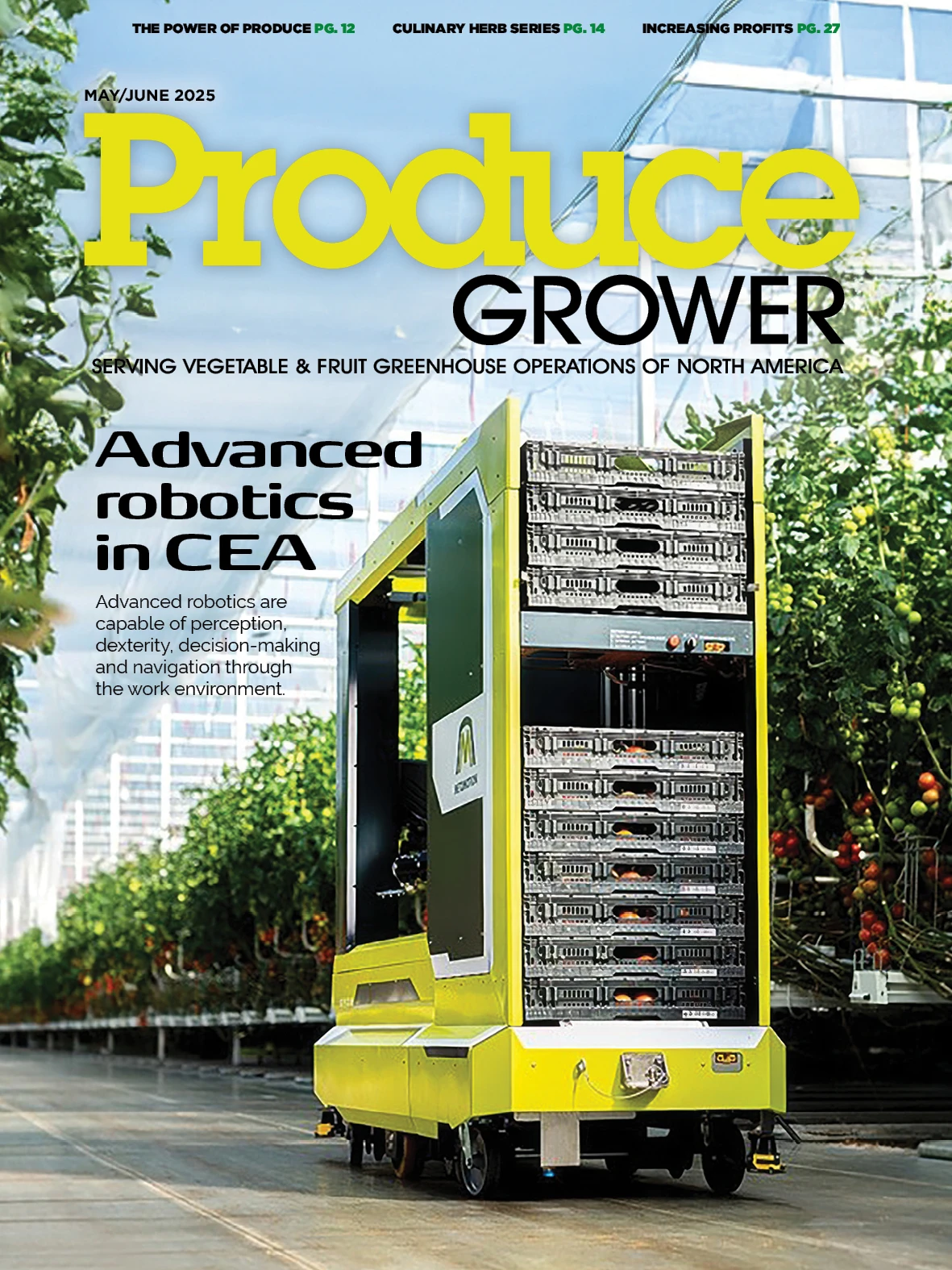

Tomato harvesting machines

Using artificial intelligence and cameras to detect and harvest fruit, these machines usually require a pipe rail system for movement. Some can move automatically from one aisle to the next. Efficient handling methods are needed to move the fruit from the growing area to the packing area.

Tomato grading machines

These computer-controlled machines are designed with four functions: in-feeding, which gently dumps the fruit from the picking box or bin; grading, which uses cameras to examine for internal quality, texture, taste and defects: sorting, which determines fruit weight, maturity, firmness and sugar content; and packing, which conveys fruit to packing stations for boxing and palletizing.

Explore the May/June 2025 Issue

Check out more from this issue and find your next story to read.

Latest from Produce Grower

- Divert, Inc. and General Produce partner to transform non-donatable food into Renewable Energy, Soil Amendment

- Food safety regulations

- Beyond a burst of optimism

- Kroger announces leadership updates

- Source.ag raises $17.5M for applied AI in CEA, pushing total funding past $60M

- Pure Flavor realigns supply chain with new Michigan distribution center

- BioWorks introduces Sandrine Copper Soap and Cintro Insecticidal Soap

- BrightFarms debuts campaign for National Quitter’s Day