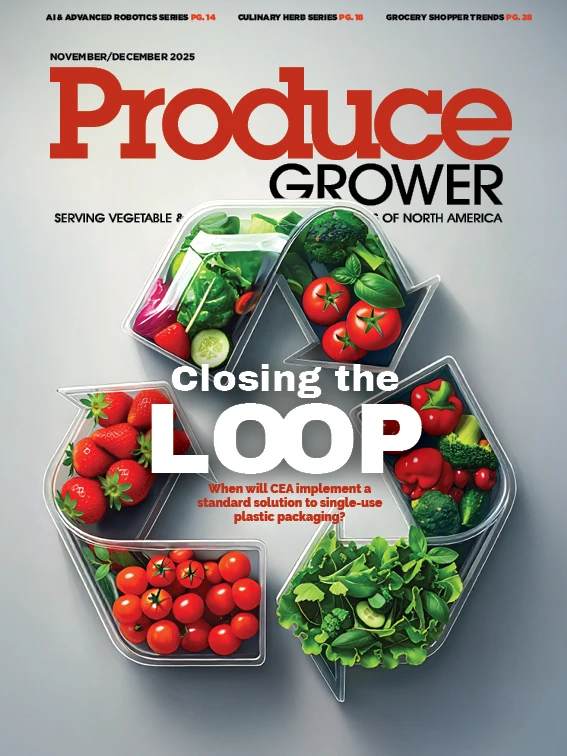

Editor's Note: This article originally appeared in the November/December 2025 print edition of Produce Grower under the headline “Closing the loop.”

Survey after survey continues to indicate the consumer’s desire for more sustainable packaging, whether that means material made from recycled plastic or alternative material innovations. Growers and retailers share the same inclination.

But there’s a gap between behavior and intention. While many consumers express concern about plastic packaging or say they avoid it, actual purchasing behavior differs, especially when weighed against convenience and cost.

According to a McKinsey & Company 2025 U.S. packaging survey, consumers still prioritize product quality, price and convenience over environmental impact. More than 70% of those surveyed said quality and price are “very important” or “somewhat important” when making purchase decisions. Although sustainable packaging may be a popular concept, it can’t compromise cost, performance or convenience.

Despite the fickle consumer behavior, several universities are making major investments in developing sustainable packaging for myriad consumer goods, including material that is applicable for fresh produce.

Circular packaging solutions

According to Michigan State University research, the United States produces some 40 million tons of plastic waste annually, much of it in the form of packaging materials. And current data suggest that only around 5% of plastic waste is recycled. Nearly 40% of plastic waste in the U.S. comes from packaging, contributing to pollution, landfill issues and the spread of micro- and nanoplastics, reports the MSU School of Packaging (SoP).

In response to that statistic, the SoP recently launched the new Center for Plastic, Paper and Hybrid Packaging End-of-Life Solutions (C3PS) to explore novel solutions to the challenges posed by plastic and plastic-coated paper waste. C3PS will work to address the end-of-life issues associated with packaging materials through pre-competitive research that will strengthen U.S. manufacturers on the global stage.

“MSU has the world’s biggest and top-ranked school of packaging, and its unique industry partnerships set our researchers apart,” says Kevin Guskiewicz, president of Michigan State University. “The SoP has a reputation for sustained excellence over time, and this center will further solidify its position as the go-to place for solving the packaging industry’s most pressing problems.”

C3PS is supported by the U.S. National Science Foundation with an initial five-year grant, and it’s NSF’s first Industry-University Cooperative Research Center “dedicated to enhancing the impact of precompetitive research in the field of packaging through collaborations among industry innovators, academic teams and government leaders,” according to Michigan State.

This initiative’s three primary objectives are:

- Conduct high-impact research in packaging to address the shared needs of companies of various sizes.

- Strengthen the United States’ global leadership in the advancement of innovative packaging technology.

- Develop a highly skilled workforce in the manufacturing sector.

“C3PS seeks to advance the science and engineering of ‘cradle-to-cradle’ packaging, where plastic, paper and hybrid packaging materials are designed to integrate with their eventual disposal systems,” says Muhammad Rabnawaz, director of C3PS and associate professor in MSU’s School of Packaging. “C3PS researchers envision a circular packaging economy that builds this thinking into the manufacturing process so that packaging materials aren’t discarded — they’re reused, recycled or biodegraded.”

The center’s work will focus on two main areas:

Plastic: Research will focus on developing safe, zero-waste plastic packaging solutions by designing recyclable and biodegradable plastics. This development will function alongside improvements to existing recycling technologies, creating cost-effective methods for reducing plastic waste.

Paper and paper-plastic hybrids: Research will focus on developing safe, recyclable and biodegradable paper and paper-plastic hybrid materials. Increasing circularity will require new recycling methods for emerging hybrid products, developing recyclable paper additives and finding ways to create consumer-ready products from recycled paper.

“By advancing new material development and disposal systems, C3PS will enable both upstream and downstream innovations that U.S. industry can scale and adapt,” Rabnawaz says.

Sustainability for exports

Clemson University’s Sustainable Packaging Innovation Lab (SPIL) awarded $2.5 million to support the development of cutting-edge sustainable packaging solutions in the summer of 2025.

These efforts are aimed at ensuring U.S. specialty crops remain competitive in global markets, particularly the European Union and Canada, where new regulations are phasing out plastic and requiring recyclable or compostable alternatives for produce packaging.

The new international regulations aim to eliminate single-use and small-quantity packaging in favor of bulk bins for produce under 1.5 kilograms. The regulations also require more post-consumer recycled content in plastic packaging.

SPIL, which was founded in 2021, is a national R&D and commercialization platform that unites Clemson’s Department of Food, Nutrition and Packaging Science faculty with expertise in areas such as chemical synthesis and recycling of polymers; organic composting and lifecycle analysis; antimicrobial and biodegradable films; active and intelligent packaging; package and material testing; polymer processing and mechanical recycling; and postharvest biology.

Funded projects include:

- Reducing produce wastage and increasing sustainability in the U.S. fresh berry industry through implementation of active ethylene-controlling, paper-based packaging for export and retail.

- Development of biodegradable agar-cellulose active packaging for specialty crop exports.

- Development of fully recyclable cellulose-based packaging for berry export.

In early 2025, Clemson also launched the Compostable Packaging Research and Design Center to accelerate the development of sustainable next-generation packaging.

“The Center will not only advance sustainable packaging design but also generate insights into recycled materials from design to implementation,” says Andrew Hurley, Clemson FRESH (Food, Research and Education in a Sustainable Hub) research director and professor. “Together with the Sustainable Packaging Innovation Lab, this initiative will help ensure U.S. specialty crop exports meet international packaging standards.”

The center was designed to respond to emerging global regulations, including requirements for compostable produce labels, increased post-consumer recycled content in plastic packaging and reduced use of shrink wrap. These regulations, driven by United Nations efforts toward a global plastics treaty, aim to eliminate single-use packaging and promote sustainability, according to Clemson FRESH.

The center is equipped with an in-vessel composter with automated controls and reverse aeration bays, which provides packaging compostability evaluations in as few as 28 days.

“These capabilities represent a unique opportunity for companies to address complex composting challenges,” says James Sternberg, Clemson University assistant professor of sustainable packaging. “We can evaluate biodegradability rates in the lab and conduct large-scale field tests to provide a complete picture of the composting process.”

Reducing ‘white pollution’

Researchers at Virginia Tech have found a way to make biodegradable packaging stronger while using less energy in the process. The research team from the College of Agriculture and Life Sciences and the College of Natural Resources and Environment developed a low-pressure treatment that improves plant-based packaging materials.

The research team says this discovery could help companies move away from plastic without sacrificing strength or durability.

“Petroleum-based plastics have long been the mainstay of packaging applications,” says Haibo Huang, associate professor in the Department of Food Science and Technology. “However, their persistence in the environment has led to increased concerns about ‘white pollution.’ Biodegradable packaging materials are gaining interest as alternatives, but they often struggle to match the performance properties of petroleum-based plastic.”

The researchers found a new process that makes cellulose-based materials much stronger and more useful in packaging while using less energy than traditional methods.

“Natural materials like cellulose have great potential for packaging, but they aren’t compatible enough for large-scale use,” said Young-Teck Kim, associate professor in the Department Sustainable Biomaterials and co-principal investigator on the project. “It is exciting to see that the biodegradable cellulose-based packaging film can offer robust physical and mechanical properties for many applications.”

Cellulose, one of the most abundant organic materials on Earth, has long been eyed as a potential biodegradable packaging alternative. However, its poor structural properties have made large-scale industrial applications impractical, the researchers revealed. The Virginia Tech team believes they can change that by using physical rather than chemical treatment to strengthen the material.

The process, which applies low-pressure cycles instead of traditional high-energy methods, enhances the internal structure of cellulose, improving gas barrier properties, mechanical strength and transparency — three critical factors in food packaging.

“We were surprised to find that multiple cycles of low-pressure treatment outperformed conventional high-pressure methods,” Kim says. “Not only did the material become more functional, but it also suffered less damage, making it a more viable option for packaging applications.”

The team says the study could pave the way for the commercial adoption of bio-based packaging.

“Our research provides an accessible and cost-effective way for industries to transition to biodegradable packaging without compromising quality,” Kim says.

The project has already gained interest from industry partners looking to scale production, according to the team. Researchers, who include professors Audrey Zink-Sharp and Maren Roman in the Department of Sustainable Biomaterials, are now exploring additional applications, including food-contact-safe antimicrobial packaging.

For the CEA industry, packaging communicates not just function, but the sustainability credentials of the fresh produce. The packaging choice provides an opportunity to reinforce the industry’s premium and sustainable positioning.

Explore the November/December 2025 Issue

Check out more from this issue and find your next story to read.

Latest from Produce Grower

- [WATCH] Advances in growing media for CEA production

- Award winners announced for 2026 PHS Philadelphia Flower Show

- U.S. horticulture operations report $18.3 billion in sales: USDA

- Industry leaders call for action to support economic aid for specialty crops

- Sollum Technologies launches SF-INFINITE, a new LED fixture for commercial greenhouses

- [WATCH] Taking root: The green industry’s guide to successful internships

- ACT announces 2026 event series focused on resilience, energy, efficiency in greenhouse growing

- BioWorks appoints Chris Rose interim general manager