.jpg) ACourtesy of Freight Farms new product out of Boston could soon blur the lines between what’s considered in season and what isn’t. Freight Farms has introduced a scalable farming platform that can produce food at a commercial volume, all locally. It is a “turnkey system for sustainable commercial farming,” according to the company.

ACourtesy of Freight Farms new product out of Boston could soon blur the lines between what’s considered in season and what isn’t. Freight Farms has introduced a scalable farming platform that can produce food at a commercial volume, all locally. It is a “turnkey system for sustainable commercial farming,” according to the company.

Freight Farms founders Jon Friedman and Brad McNamara have worked together since 2005, both with a desire to eliminate unnecessary costs in food production. They started working with rooftop greenhouses using hydroponics but soon realized these systems weren’t very viable for business owners.

“The greenhouses weren’t as efficient,” Friedman says. Many people questioned the greenhouses because of the unused headspace. So they started looking at different, more efficient ways for businesses and individuals to do local agriculture.

Friedman and McNamara got the idea for Freight Farms from Puma City, a retail shop made of 24 shipping containers that travels to different cities and can be disassembled and reassembled.

“The more we looked into it, we put the pieces together and saw it as a way to grow plants,” Friedman says.

The Freight Farms containers are made using recycled, insulated freight containers sized 40 feet long by eight feet wide and 12 feet tall. The containers are used to build an infrastructure that includes hanging and bracketing.

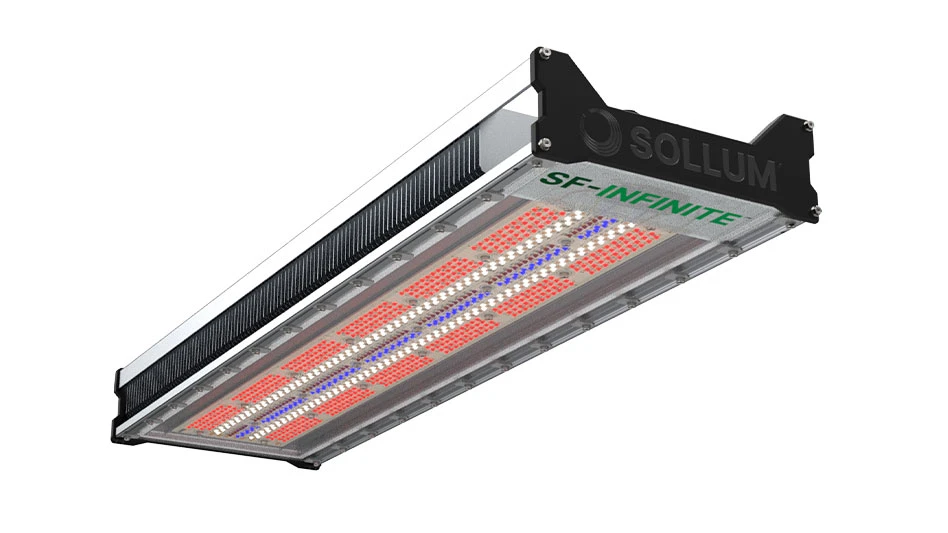

How it’s done -- The growing is done through vertical orientation, all on a hydroponic system. LED lights inside are customized to give the correct amount of light. A tablet on the wall controls airflow, temperature, humidity and CO2 and manages water, nutrients, pH balance and additives.

“You can grow in any climate, in any part of the world, in any season,” says Rebecca Liebman, Freight Farms communications coordinator.

Liebman says she expects that Freight Farms will eventually impact global produce distribution “A tomato in the grocery store has traveled pretty far to get to your plate,” she says. “This eliminates that. No matter where you are, you can have local produce. This is unheard of in most parts of the world.”

Freight Farms officially rolled out its first unit in November of 2012, complete with a launch party. The party was put on by The Institute for Energy & Sustainability, and special guests included Congressman James McGovern, Mayor Joseph Petty and Senator Richard Moore.

The company currently has three containers in use, two of them locally in Boston. One of the Boston containers is actually two stories. The top story is used for growing produce while the bottom is used for packaging. This allows the produce to be packaged without being exposed.

Another container is located in Worcester, and two more containers are in construction, one of which will stay in Boston while the other goes to Minneapolis.

Future crops -- As of now, the containers are able to grow leafy greens, such as lettuce, kale, spinach, arugula, basil, oregano and sprouts. By fall 2013, Freight Farms plans to add vine crops such as tomatoes, cucumbers and peppers. The company also wants to add mushrooms as a viable Freight Farms crop by then.

Another benefit of the containers is they eliminate pesticides and herbicides while also creating a smaller footprint. “Because we do not use soil and it is controlled growing, we do not have to use pesticides or herbicides,” says Liebman. “Diseases thrive in soil, but because hydroponics only uses water and the container is closed, this is not an issue.”

Even though Freight Farms is new to the produce-growing world, the company is already planning the next level. One of the plans is to expand in Boston, unleashing multiple, very visible units into the city.

“We’re going to be rolling out some big things this summer,” says Friedman. “Everyone should expect to see a lot more of us.”

.jpg) Courtesy of Freight Farms

Courtesy of Freight Farms

Latest from Produce Grower

- The Growth Industry podcast Episode 10: State of the Horticulture Industry

- Bimi Baby Broccoli partners with Cal-Organic Farms

- Millennium Pacific Greenhouses launches California Grown Cucumber Program

- Scientists develop vitamin A-enriched tomato to fight global deficiency

- UTIA and UT Knoxville research teams will develop automated compost monitoring system

- [WATCH] Taking root: The green industry’s guide to successful internships

- [WATCH] Advances in growing media for CEA production

- Award winners announced for 2026 PHS Philadelphia Flower Show